Concepts to Creations

What starts as an idea often becomes a machine, a product, or a learning tool. This collection of work showcases my journey, from CAD explorations to commercial automation, and my passion for bringing ideas to life through engineering and creativity.

Riku – Automatic Rice & Curry Maker

Role: Area product Owner

Overview:

Riku is a fully automated kitchen appliance designed to prepare rice and curry dishes with minimal human intervention, Aiming to redefine home and commercial cooking automation.

My Contribution:

-

Owned the development of complex working subsystems, including spice dosing, liquid handling, and ingredient dispensing.

-

Led multiple prototype cycles focusing on reliability, maintainability, and manufacturability.

-

Collaborated with culinary experts to align design parameters with recipe and food safety standards.

-

Coordinated testing, calibration, and integration of mechanical–electronic subsystems, ensuring high functional stability.

Impact:

Contributed to making Riku one of India’s pioneering smart cooking products, setting the foundation for automated multi-dish cooking systems.

Chai Monk 2.0 – Smart Chai Maker for Chaayos (B2B)

Role: Product Owner / Client POC (Chaayos)

Overview:

Chai Monk 2.0 is a next-gen chai automation system developed exclusively for Chaayos, designed to deliver authentic taste with café-level consistency and efficiency.

My Contribution:

-

Acted as the primary point of contact (POC) between Chaayos and Klynk, managing all B2B requirements, feature discussions, and performance validations.

-

Led the end-to-end product journey. From concept, prototyping, and engineering to pilot deployment and production launch.

-

Coordinated a 13-member cross-functional team, ensuring technical alignment with operational needs of Chaayos outlets.

-

Supervised pilot trials in Chaayos cafés, gathered field insights, and implemented critical improvements before production release.

Impact:

Successfully delivered a production-ready machine deployed in live Chaayos cafés, achieving 99% taste consistency across 80,000+ recipes and contributing to ₹1 crore revenue in 6 months.

Flavour Monk – Precision Flavour Dispenser for Chaayos (B2B)

Role: Product Owner / Client POC (Chaayos)

Overview:

Flavour Monk is a precision add-on module engineered for Chaayos to automate flavour dispensing and enhance beverage customization.

My Contribution:

-

Served as the lead POC with Chaayos, handling all B2B discussions, flavour calibration sessions, and integration requirements.

-

Independently developed the system. Mechanical, Electronics, and Firmware. Achieving 0.07g precision.

-

Integrated Flavour Monk seamlessly with Chai Monk 2.0 for synchronized recipe automation.

Impact:

Enabled Chaayos to maintain flavour consistency at scale, reducing manual intervention and supporting rapid rollout across café outlets.

Koma – Automatic Cocktail Maker

Role: R&D Mechatronics Engineer

Timeline: 2019 – 2020

Overview:

A fully automated cocktail-making machine designed for bars and lounges, capable of mixing and dispensing accurate drink proportions with a single tap.

My Contribution:

-

Co-developed the complete prototype with a two-member team. Achieving >95% dispensing accuracy during pilot testing.

-

Designed and integrated mechanical structure, electronics, and embedded firmware using Raspberry Pi.

-

Conducted usability testing with 10+ bartenders to refine ergonomics and interaction design.

-

Built custom PCBs in-house using 3D printing and copper etching to reduce prototyping costs by 20%.

Impact:

Delivered a fully functional market-ready prototype within 9 months; though the project paused due to COVID-19, it validated the concept and laid the foundation for scalable beverage automation.

DIY Science Experimental Kits (Ray Optics & Total Internal Reflection)

Role: Product Designer & Developer (Team of 2)

Institution: CPDM, IISc Bangalore

Overview:

Developed interactive science kits to make complex physics concepts like Ray Optics and Total Internal Reflection easy to understand for school students through hands-on experimentation.

Our Contribution:

-

Identified gaps where physics concepts lacked practical demonstration tools in classrooms.

-

Designed, engineered, and fabricated DIY experimental kits using accessible materials and classroom-safe mechanisms.

-

Conducted testing and demonstrations in multiple Bangalore schools, gathering student and teacher feedback.

-

Showcased the kits during IISc Open Day, where 10,000+ students interacted and learned through real-time experimentation.

Impact:

The project continued to make an impact years later, when I represented CPDM, IISc at the All India DIC Meet, IIT Hyderabad, showcasing the DIY experimental kit for its contribution to hands-on science education and innovation-driven learning.

Automatic Hot Sandwich Maker / Vending Machine

Role: Solo Developer (End-to-End Product Builder)

Project: Undergraduate Final-Year Project 2019

Overview:

A fully automated sandwich-making machine designed to streamline preparation, reduce manual effort, and deliver consistent results — built entirely as a solo engineering project.

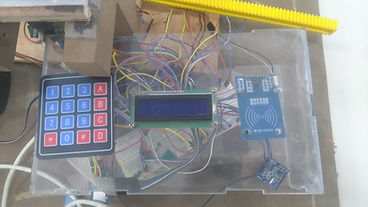

My Contribution:

-

Conducted user research and requirement analysis to understand real-world pain points in quick food automation.

-

Designed and developed the complete system architecture, including mechanical mechanisms, ingredient handling, heating, and assembly logic.

-

Built custom electronic control systems and wrote the embedded firmware & logic to automate the process end-to-end.

-

Integrated all subsystems and fabricated a working prototype capable of preparing a sandwich with minimal human intervention.

Impact:

Demonstrated my ability to own a product from idea to working prototype, combining mechanical design, electronics, coding, and user-centered engineering into one functional innovation.

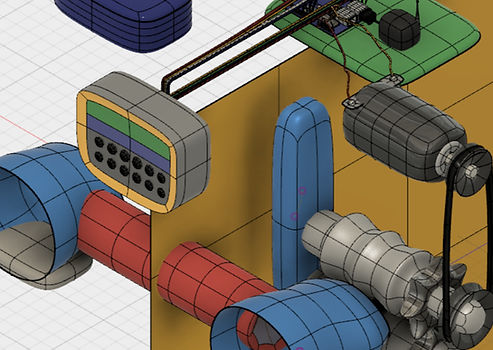

Animation of the Design

Pendrive Bracelet Watch – Smart Wearable Concept

Competition: Autodesk India Design Challenge

Recognition: Selected in Top 30 Designs Nationwide

Overview:

This concept was developed for a national Autodesk competition where the challenge was to design a smart wearable that is both aesthetically appealing and functionally useful.

My Approach:

-

Spent significant time exploring ideas that blended fashion with utility.

-

Chose to combine a bracelet and watch, integrating a hidden USB drive for everyday practicality.

-

Took visual inspiration from a motorcycle chain, incorporating its rugged form into a sleek, wearable design.

-

Modeled and rendered the complete concept using CAD tools to showcase material, fit, and real-world feel.

Outcome:

The design was selected among the Top 30 entries in India, earning national recognition for innovation, usability, and creative execution.

Bamboo Prep Kitchen – Sustainable Kitchen Workstation

Design Goal: Create a functional kitchen prep station using bamboo as the primary material.

Concept Overview:

This concept explores a sustainable and compact food preparation station, designed specifically with bamboo to promote eco-friendly living. The workstation integrates chopping, storage, and preparation zones in a single layout, maximizing space while maintaining durability.

Design Focus:

-

Use of renewable bamboo material for strength and sustainability.

-

Ergonomic layout for efficient food prep workflow.

-

Minimalist form inspired by traditional craftsmanship and modern utility.

Purpose:

To demonstrate how natural materials like bamboo can be transformed into modern, space-saving kitchen solutions with both aesthetic and functional value.

Rowing Machine – Concept Redesign (CADCROWD Competition)

A CAD concept developed to redesign the traditional rowing machine with improved functionality and home/gym aesthetics. The goal was to enhance the strengths of the industry-leading Concept2 Model D. Such as durability, simplicity, and portability, while improving ergonomics, accessibility, and visual appeal.

Design Focus:

-

User-friendly ergonomics and reach during workouts

-

Modernized form suitable for home and commercial gyms

-

Enhanced adjustment and interaction features

-

Maintain durability while elevating design aesthetics

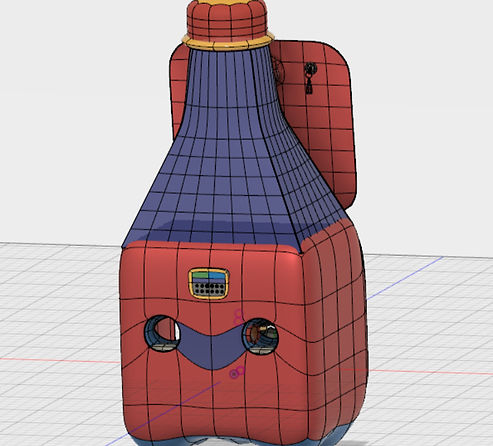

Bottler Machine – Swachh Bharat Concept (Autodesk 3D Design Challenge)

Won 1st Prize | IIITDM Campus-wide Competition | 2nd Year Student

The Bottler Machine is a concept developed for an Autodesk Fusion 360 Design Challenge on the theme “Swachh Bharat”. Unlike typical CAD entries, this project focused on solving a real problem, Plastic waste and littering.

The Idea:

A machine that accepts discarded plastic/glass bottles or cans, and in return, rewards users with mobile recharge credit, calculated by the bottle’s weight. A simple incentive to reduce waste and promote recycling.

My Journey:

-

Competition duration: 30 days

-

Spent 25 days searching for the right idea. Because anyone can create a CAD model, but a meaningful idea is rare

-

Once the idea clicked, I completed the entire CAD design in just 5 days

-

Competing against seniors, my idea-first approach helped me win 1st Prize across the college

-

Why It’s Special:

This project wasn’t just about design — it was about impact, problem-solving, and believing that one strong idea can win over experience.

Clean the Space – Space Debris Removal Concept

3rd Prize | Intra-College CAD Competition | Idea over Complexity

Overview:

This project was created for an intra-college competition where participants were challenged to design a solution to clean space debris using CAD. The competition was open to all years, and most participants presented complex technical models.

My Approach:

-

The deadline was 30 days, but I got my idea just 1 day before submission.

-

Instead of chasing complexity, I focused on a simple, practical idea that could realistically capture debris.

-

Designed, animated, and prepared the full presentation within 24 hours.

Impact & Outcome:

-

Despite competing against advanced and visually complex designs, this concept won 3rd Prize, proving that a strong idea can outperform pure technical showmanship.

-

This project reinforced my core belief:

Great design isn’t about complexity. It’s about clarity and purpose.

Design Explorations